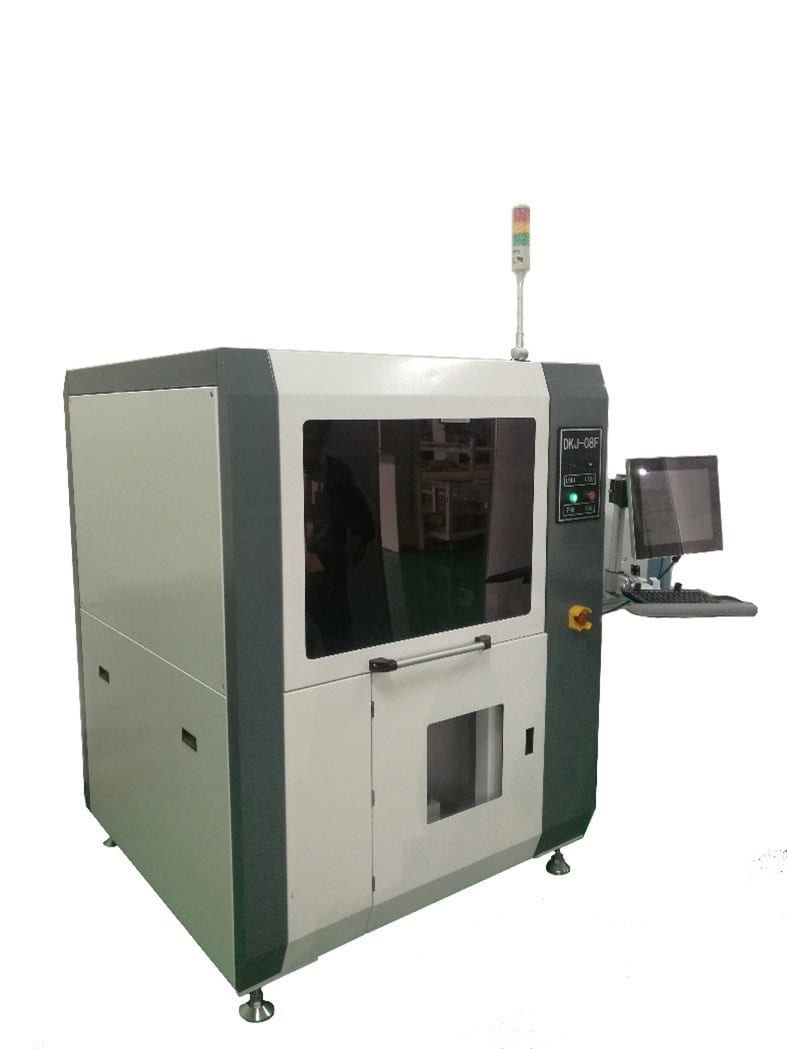

This equipment is primarily used for forming through-holes, alignment holes, and cavities on green ceramic tapes. It is a key machine in the manufacturing of LTCC/HTCC multilayer substrates. The system uses mechanical punching and supports both frameless and framed processes. It features fully automatic loading and unloading, and can be equipped with multiple punching units. A CCD system enables automatic centering of the punching units and precise positioning for secondary processing of patterns. The equipment accepts DXF format graphic files. It has a user-friendly interface and is easy to operate, with multiple product series available.

Operating Mode: With or without frame

Loading/Unloading Method: Automatic

Green Tape Size: 203mm × 203mm

Effective Punching Area: 177mm × 177mm

Punching Diameter: φ0.08mm – φ5.0mm

Square Hole Size: 0.5mm – 5mm

Punching Speed: ≤1500 holes/min

Green Tape Thickness: ≤0.5 mm

Punching Accuracy: ±10μm within effective area (excluding mold error)

Secondary Processing Accuracy: ±20μm within effective area (excluding errors from mold and mark hole positioning)

Number of Punching Units: 8 punching units (4 high-speed, 4 low-speed)

Data Processing: Equipped with automatic data conversion software; supports DXF format files

Reviews

There are no reviews yet.